Home > Company Introduction

Company Overview

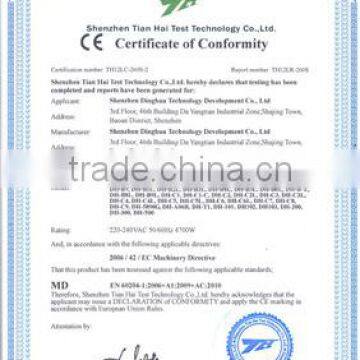

Shenzhen DingHua Technology Development Co., Ltd., is a professional manufacturer specializing in develop various BGA rework stations with its accessories.Thanks for our strong R&D capability; we have been upgrading our BGA rework station from manual operation to robot as per customer's different requirements. Now we are still researching and developing our unique technology to be used in our next generation BGA rework station, which combines the most advanced with integrated technology. Our key components are all using international brands to ensure the top quality and have been got good reputation from over 60 countries for its high performance.Our BGA rework stations are widely used in many repair fields, such as computer, laptop, game player, communication equipment, mobile phone, etc. In a word, our BGA rework station applies for all PCBA that has BGA on it.Our manufacturer has honored ISO2001: 2008, ISO14001:2004. Our rework stations have CE certificates. We bear in mind that best "after-service" is our promise to our customers and It's also our manufacturer's long-term strategy. Warm welcomed to contact us today!

-

ManufacturerBusiness Type

-

2011Year Established

-

1,000-3,000 square metersFactory Size

-

US$2.5 Million - US$5 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

101 - 200 People Total Employees

-

1-10 People Sales Staff

-

US$2.5 Million - US$5 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Shenzhen, Hongkong Port of Shipment

-

Laser Welding Machine Main Industry

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.